How Does a Beer Tap System Work

The first step to making the most of your Beer Tap System is understanding how it delivers beverages to patrons at the perfect temperature. Knowing how the system works helps ensure fast service and reduced labor costs.

Every component plays a role in preventing flat, foamy, or warm beer. GS Draft is here to help—read on to discover how your beer tap system works for easier setup, troubleshooting, and long-term functionality.

Types of Beer Tap Systems: How Set Up Impacts Functionality

Generally speaking, beer tap systems — regardless of size or complexity — are categorized by how far the dispensing system is from the kegs and cooler. Direct draw systems dispense cold beer and other beverages from kegs located directly beneath or behind the system, while long draw systems use long tap lines to transport beverages from keg to tap. Both systems come in a variety of forms, from draft beer towers, tap walls and kiosks, to other personalized set-ups.

Direct Draw Systems

These compact systems place kegs directly beneath or behind the tower. Glycol cooling isn’t required, and the cooler maintains proper temperature while doubling as keg storage. These systems include gas tanks, regulators, air and beer lines, couplers, faucets, and tap handles—ideal for smaller setups.

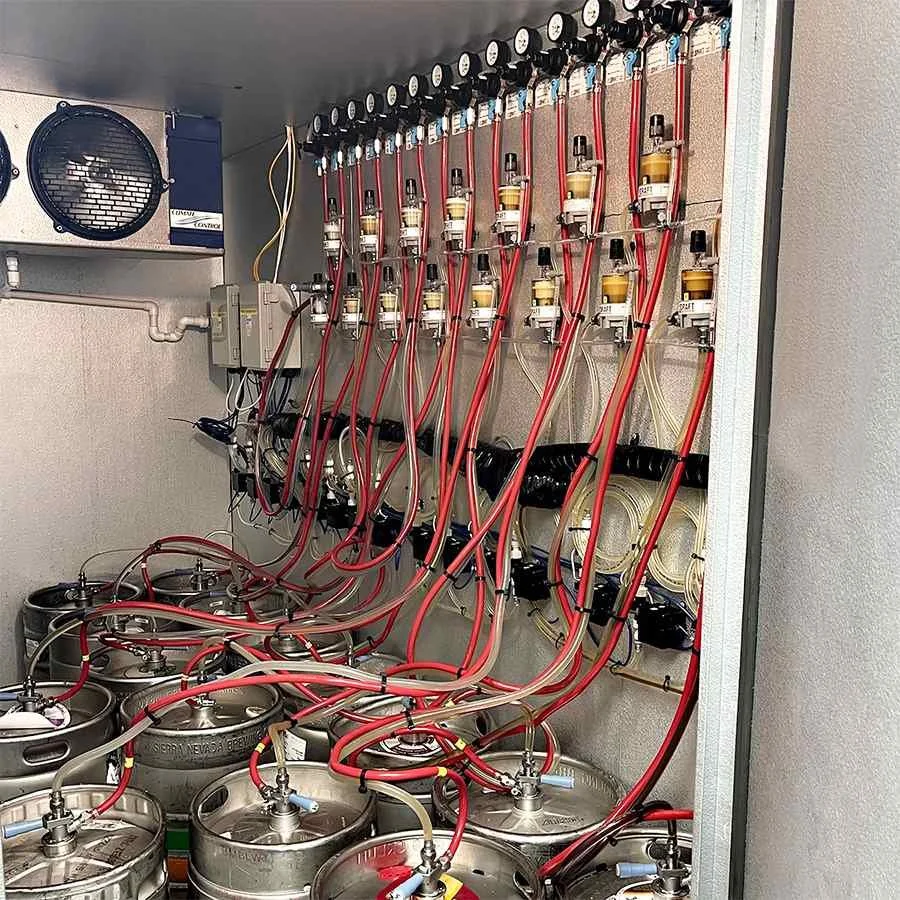

Long Draw Systems

Used in larger venues, these systems transport beverages using glycol trunk lines and a power pack to maintain temperature. Gas travels from tanks through a blender and regulators, pushing beer to the tower. Couplers connect kegs to lines; faucets and tap handles serve the beer. Perfect for centralized storage in stadiums and large restaurants.

Contact Us

The Essential Components of a Draft Beer System

Both short and long draw systems use similar core equipment. Here's how each essential component contributes to smooth operation:

The Cooler

Proper storage is key to safe beer service. Most draft beers must be kept at 36–38°F to maintain freshness, texture, and flavor. Coolers vary in size—from compact units in direct draw systems to walk-in models—but all house the kegs and mark the starting point of the dispensing process.

Beer Kegs

Kegs serve as the primary storage for beverages and are available in multiple sizes, typically 5, 7.75, or 15.5-gallon stainless steel formats in the U.S. Each keg has a valve on top where gas enters and beer exits through an internal tube. CO2 or nitrogen applies pressure, pushing the beer upward through the system.

Gas Tanks

Pressurized tanks of CO2 or nitrogen power the system, pushing beer from keg to tap. These connect via air lines and couplers. CO2 is standard, while nitrogen is used for beverages like stouts and cold brew. Tanks generally come in 5 or 10 lb sizes, with a 5 lb CO2 tank dispensing approximately 5–7 kegs.

Gas Blenders

Ideal for venues serving a mix of beverages, a Gas blender combines CO2 and nitrogen to deliver the right carbonation and texture. Fill one tank of each gas, and the blender automatically adjusts the mix per beverage requirement.

Primary & Secondary Regulators

Regulators ensure beer is dispensed at the correct pressure. They're divided into two types, each serving a distinct function:

Primary Regulators

Installed at the gas source, primary regulators set the base pressure for the entire system. Built-in gauges make it easy to monitor and adjust settings.

Secondary Regulators

Positioned downstream from the primary regulator, secondary regulators allow precise pressure control for individual tap lines—ideal for serving multiple beer styles with different pressure needs.

Air Lines Vs. Beer Lines

Air lines and beer lines have distinct functions and are often color-coded for clarity:

Air Lines

Made from food-grade vinyl or braided vinyl tubing, air lines carry CO2 or nitrogen from the gas tank through the regulator to the keg coupler. This pressurized gas drives the beer through the system.

Beverage Lines

Beverage lines carry dispensed beverages from the keg to the faucet. Unlike air lines, only beer or other draft drinks flow through these lines.

Glycol Trunk Line

In glycol-cooled long draw systems, the trunk line transports beverages from the cooler to the faucet while maintaining a consistent temperature. It uses a chilled mix of food-grade glycol and water to keep multiple beer lines cold during transit.

Glycol Power Pack

Also called a glycol chiller, this unit supports long draw systems by circulating chilled glycol through the trunk line. It includes an air-cooled compressor, a water-cooled compressor, a glycol bath, and a recirculating pump to ensure consistent cooling over long distances.

Couplers

Couplers connect kegs to both gas and beer lines. When locked in place, they open the keg valve, allowing gas in and beer out. Their airtight seal helps preserve carbonation and temperature. With six standard types available, each GS Draft system includes the correct coupler for your setup.

Draft Beer Tower

The draft beer tower is the most visible part of the system, dispensing beer from the tap lines to the glass. Made from stainless steel or flexible barrier tubing, it houses the faucets and connects to the beer lines. Most towers include the components below:

Faucets

The final point before beer reaches the glass. Standard models work well for basic pours, while premium versions offer smoother flow, better control, and cleaner dispensing.

Tap Handles

These levers attach to the faucets and control the pour. Pulling the handle opens the faucet; pushing it back stops the flow. Available in various shapes and styles to suit any design requirements.

Drip Trays

Positioned below the faucets, drip trays catch overflow to keep the area clean. Models with built-in drains connected to a hose for easier waste disposal.

Digital Beer Menus

Enhance the customer experience with Beer Wizard Beer Menus—customizable, digital templates that clearly display your beverage offerings.

GS Draft Is Your Trusted Expert for Beer Tap Systems

At GS Draft System Solutions, we specialize in designing, installing, and maintaining beer tap systems to help your business run efficiently and profitably. Our expertise ensures reduced waste, consistent performance, and greater customer satisfaction.

From setup to ongoing support, we take pride in delivering high-quality solutions tailored to your needs.

Contact us today at (949) 421-3882 or email sales@gsdraft.com to explore our installation options.